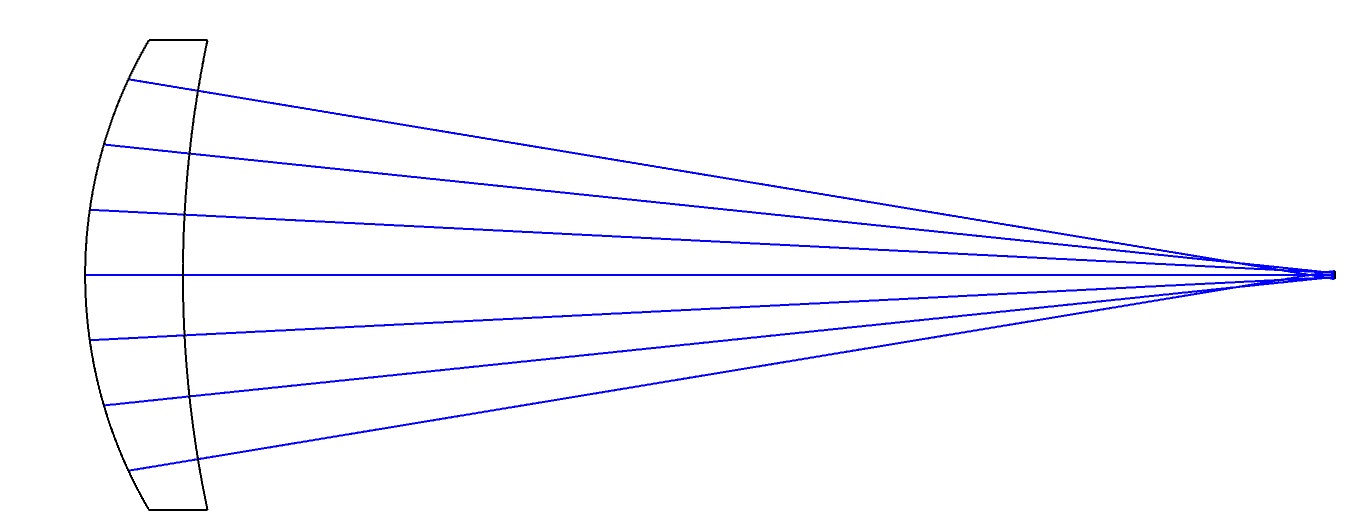

Meniscus Lenses

Meniscus lenses are lenses that have a one surface that is positive and one that is a negative radius.

Kingsview Optical manufactures custom meniscus lenses when stock lenses won’t do. From prototype batches to full production Kingsview has facility to offer both. Our specialty is offering rapid turnaround on lenses. We can also offer a number of coating options depending on your requirement.

Standard Lens Tolerances

| Size: 0.8mm to 150mm |

| Diameter Tolerance: -0.05 mm |

| Centre Thickness Tolerance: ±0.05 mm |

| Decentration (wedge): ± 2′ |

| Irregularity: λ/4 |

| Spherical Error: 0.5% of radius or better |

| Surface Quality (Scratch/Dig): 40/20 |

| Coating Broadband AR, V coat, Mgf2 etc |

| Finishing Edge black painted, steps, bevels etc |

| Materials Schott, Ohara, CDGM, Fused Silica |

Lens Tooling

Dependent on the lens geometry and numbers it will be decided to either manufacture the lens conventionally or using the CNC lens line. Generally the main reasons for the decision is based on the radius needed. Meniscus lenses that have close to equal radii usually need to be polished on the CNC as there is no polishing power to polish conventionally.

If the lens is needed to be polished on the CNC there will be a tooling charge as custom tools will be manufactured. If it is done conventionally provided you use one of the many tools we have in stock you won’t have the expense of the tooling charge. This can be beneficial when the numbers are small. Here you can find our tooling list in Zemax format which you can then use to optimise your design to our tools.

Get in touch

We can also offer a precision optical components such as spherical lenses, optical prisms filters and precision windows. A custom lens design service is also available allowing us to create a tailor made solutions.

Should you need a quote please get in touch for a no obligation quotation and we hopefully will be able to help.